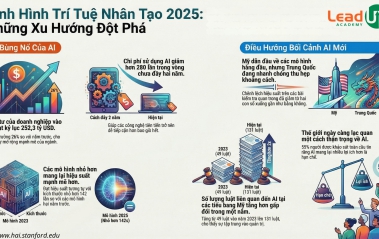

Proposed Action Recommendations for Vietnamese Enterprises Based on the AI Index Report 2025

Among the numerous AI index reports released in 2025, the AI Index Report 2025 by Stanford HAI stands out as one of the most comprehensive and insightful publications. Its breadth and depth provide a holistic view of AI’s development trajectory over the past year. This eighth edition—the most extensive to date—paints a panoramic picture of 2024, a pivotal year in which AI transitioned from a subject of technological curiosity to a genuine economic and scientific driving force.

AI Is Not for Organizations Lacking Operational Discipline

Over the past two years, Artificial Intelligence (AI) has become one of the most frequently discussed topics within the Vietnamese business community, particularly among small and medium-sized enterprises (SMEs). From business networking events and digital transformation seminars to internal management discussions, AI is often positioned as a “lever” capable of accelerating growth, optimizing costs, and strengthening competitive advantage.

Vietnamese Businesses: Three Major “Bottlenecks” in the Digital Transformation Journey

Digital transformation is no longer a new concept. From large corporations to SMEs, everyone talks about applying technology, AI, and data to boost productivity and optimize operations. However, in reality, most Vietnamese businesses are still “transforming” in words but not truly “changing” in practice. Many technology projects remain unfinished, software systems are left unused, employees feel frustrated, and leaders grow impatient — “We’ve invested, but where are the results?” The problem doesn’t lie in technology itself. It lies in people and the approach.

Vietnamese Businesses: Three Major “Bottlenecks” in the Digital Transformation Journey

Digital transformation is no longer a new concept. From large corporations to SMEs, everyone talks about applying technology, AI, and data to boost productivity and optimize operations. However, in reality, most Vietnamese businesses are still “transforming” in words but not truly “changing” in practice. Many technology projects remain unfinished, software systems are left unused, employees feel frustrated, and leaders grow impatient — “We’ve invested, but where are the results?” The problem doesn’t lie in technology itself. It lies in people and the approach.

Applying AI in Management & Operations

In our recent training programs on AI applications, we observed a common reality: departments are overloaded with administrative tasks, reporting, procedures, and decision-making in an increasingly volatile environment. Leadership wants innovation, employees want less pressure, but the recurring question is: Where can AI be applied concretely in management and operations, and how can it avoid becoming another burden?

E-learning & AI: The Future of Corporate Training

We have encountered this story in many Vietnamese companies—from large corporations to SMEs. And we realize one thing: traditional training is no longer sufficient to meet today’s challenges. When the market changes every day, when technology penetrates every corner of work, teaching and learning must also transform. That is when E-learning and AI become the answer.

VI

VI EN

EN